GTRI News & Features

01.24.25

GTRI 2024 Annual Report

The digital edition of GTRI's 2024 Annual Report provides an overview of our accomplishments, research investments and outreach programs.

Read More >>Media Inquiries

GTRI News

- News stories

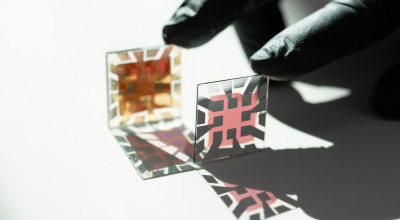

Georgia Tech researchers will soon be sending 18 photovoltaic cells to the International Space Station (ISS) for a study of how space conditions affect the devices’ operation over… Read More >>

- News stories

GTRI's latest Military Graduate Research Program (MGRP) cohort took on defense challenges with real-world impact. Three cohort members share their experiences. Read More >>

- News stories

On June 7, GTRI celebrated the U.S. Army's 250th birthday in Huntsville, Alabama, despite severe weather conditions. Read More >>

- News stories

GTRI is proud to welcome Stephanie Geigel, a U.S. Army veteran who joins our Office of the CIO through the Hiring Our Heroes program. Read More >>

- News stories

GTRI salutes its researchers who have recently achieved level advancement. Read More >>

- News stories

GTRI Operations Manager Rafael (Rafa) Dominguez, a self-described "rugby enthusiast," recently donated new uniforms to the Georgia Tech Rugby Club. Read More >>

- News stories

GTRI's Hives Early Career Independent Research and Development (IRAD) Program equips researchers who are in their first six years of employment to lead projects focused on… Read More >>

- News stories

The Georgia Institute of Technology (Georgia Tech) has named Tommer Ender as the interim director of the Georgia Tech Research Institute (GTRI), Georgia Tech’s applied… Read More >>