A research team that includes more than 120 Georgia Tech Research Institute (GTRI) scientists, engineers, and technicians is helping the U.S. Air Force update systems essential to keeping the nation’s fleet of aging E-3G Airborne Warning and Control System (AWACS) aircraft in operation until a successor capability is fielded.

The Communications Network Upgrade (CNU) project is updating the four-engine E-3G Sentry aircraft, which are modified Boeing 707 airframes built in the 1970s and 1980s. The program focuses on replacing the legacy JTIDS Class II radio terminals with the newer Multifunction Information Distribution System – Joint Tactical Radio System (MIDS JTRS). The interfaces differ significantly on the MIDS JTRS, requiring GTRI to develop new hardware to convert between the incompatible interfaces.

The project has involved a broad range of technical disciplines, including electrical, mechanical, radio-frequency, systems, test, cybersecurity, virtual reality, logistics, technical order, and training specialties. Personnel from six of GTRI’s eight laboratories and several support groups have been involved in the project.

The project included analyzing the operation of the old communications terminal being replaced, developing requirements for operation of the new communications system, designing and testing electronics that interface with other equipment on the aircraft, developing required software, assembling the interface kits, testing the equipment, updating technical orders and documentation, and training installers, maintainers, and operators. The project is now in its third year of operation.

Reviewing Documents, Analyzing System Operation

“We reviewed thousands of documents and photographs to help really understand what was involved in the new interfaces that needed to be designed,” said Mo Danesh, a GTRI principal research engineer and principal investigator for the project. “With our mechanical, electrical, and other teams, we made several trips to study the aircraft and how the communications system worked. The project has so far touched virtually every area of GTRI’s expertise.”

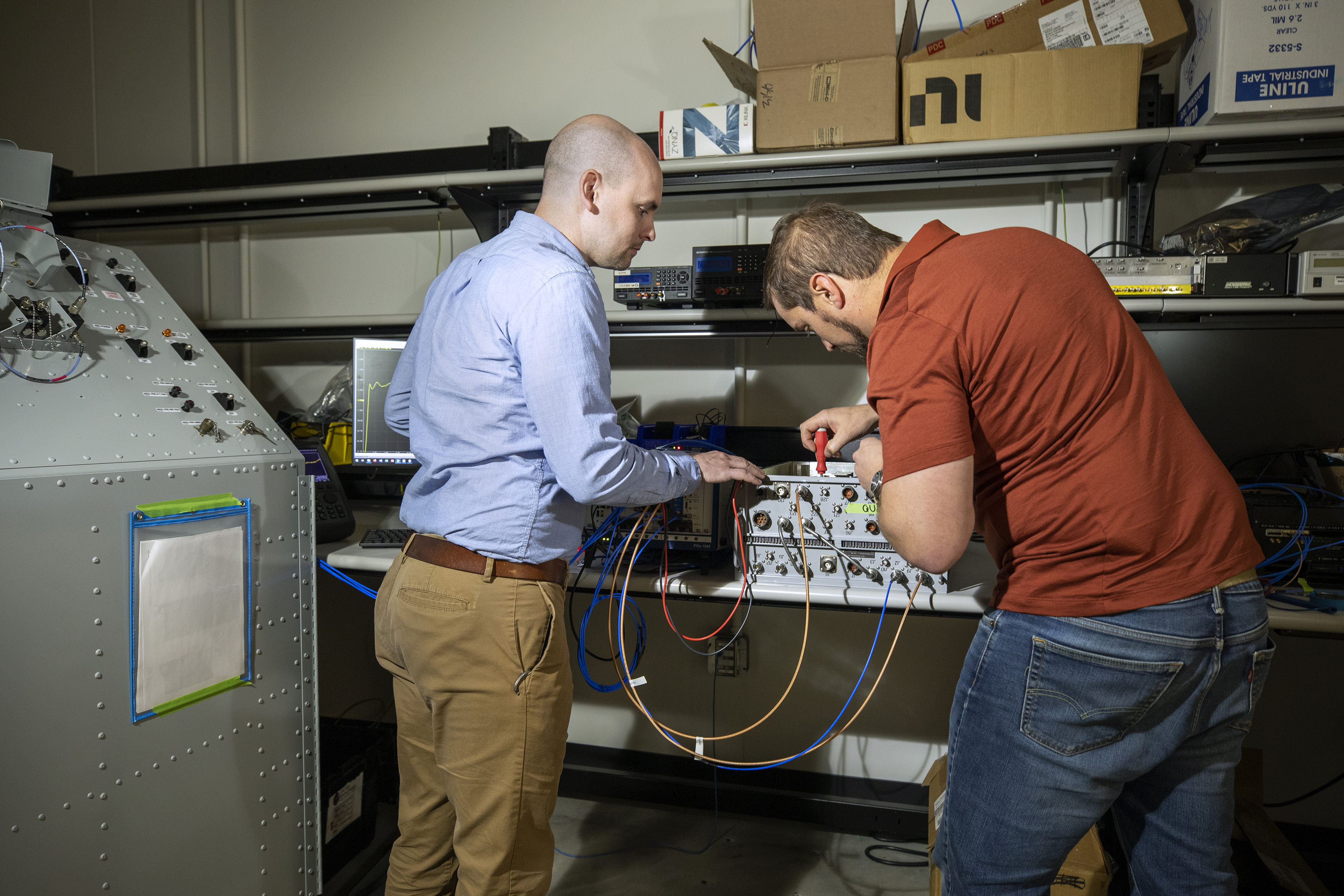

Because the aircraft are based at Tinker Air Force Base in Oklahoma City, the GTRI researchers couldn’t spend much time with the actual aircraft for the required development. They instead built a system integration laboratory at GTRI to replicate the E-3 interfaces, including the communications systems being replaced, allowing them to test new electronic designs without necessitating access to an actual E-3.

“We had to open up the old system to figure out how it worked, and use that to architect the new system mechanically and electrically,” said Christian Michelson, a GTRI principal research engineer and co-principal investigator for the project. “We had to figure out what to replicate, what mattered, and what didn’t matter.”

Beyond analyzing the equipment in operation, the researchers had to examine more than 50,000 pages of documentation, some going back more than 50 years. The replacement equipment uses a multi-channel, software-defined radio, which had to be accommodated without making significant changes to other aircraft systems connecting to it.

“We have basically gutted the cabinet that contained the legacy radio and modified it to interface between the new radio and the existing interfaces to the rest of the aircraft systems,” Michelson explained.

Designing and Building New Interface Equipment

Overall, the interface system designed by GTRI includes more than 25,000 components, some of which were challenging to obtain due to Covid-19 supply chain interruptions. To ensure the availability of components to meet the tight deadlines, GTRI hired a full-time logistics expert and maintains a parts warehouse in one of its research buildings. Some GTRI-designed components are being built by sub-vendors.

An additional complication is that not all E-3 aircraft are exactly the same because of modifications made over the years, requiring custom-made cabling or other modifications. The project is supported by the Air Force Lifecycle Management Center at Hanscom Air Force Base in Massachusetts.

Training for Installation, Operation, and Maintenance

Beyond developing the equipment and producing kits to install on each aircraft, GTRI also created training modules to help the Boeing technicians who install the new interface equipment – and both the Air Force operators who will use it and the maintainers who will support it.

To do that, GTRI called on training specialists to produce a virtual reality training environment to teach the installers how to install the new system. There are more than a dozen different operator positions on each aircraft, and the GTRI trainers also had to develop courses that provided the unique information needed by each one.

“All of the new GTRI equipment installed has passed operational testing and has worked as expected,” Danesh said. The project, which is expected to be completed under budget, will continue through 2024.

Throughout the project, the GTRI researchers were aware of the project’s urgency and kept the work on schedule despite the challenges of the Covid-19 pandemic.

“AWACS is a vital command and control platform,” Danesh said. “It directs fighters to targets, provides situational awareness for the battlefield, and communications information to the air operation commands on the ground. Everyone at GTRI understood that it is a critical asset for the U.S. Air Force.”

Writer: John Toon (john.toon@gtri.gatech.edu)

Photographer: Christopher Moore

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees, supporting eight laboratories in over 20 locations around the country and performing more than $800 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.