Milling - Vertical

- Mazak Vertical Machining Center – VCS 530C – 3 axis, X 42”, Y 22”, Z 22”

– 30 position tool changer, 1400 IBM, 10,000 rpm spindle speed, rigid tapping

- Mazak Vertical Machining Center – VCN Compact 3X – 3 axis, X 19”, Y 17”, Z 19”

– 30 position tool changer, 1400 IBM, 10,000 rpm spindle speed, rigid tapping

- Fadal Vertical Machining Center 15XT 3-axis CNC travels X 30", Y 16", Z 25,

- 21 position tool changer, 400 rapid travers, 6,000 rpm spindle speed

- Bridgeport Series II vertical mill with CNC 2-Axis Proto Trak Retrofit, table size 48" x 15"

- Four Bridgeport Series I vertical mills with CNC 2-Axis Proto Trak Retofit, table 42" or 48" x 12"

- Two Bridgeport Series I vertical mills with DRO table size 42" x 12"

- Victrax Series I vertical mill with CNC 2-Axis Proto Trak 48” x 12”

Milling - Horizontal

- Summit 4.12" horizontal boring mill with DRO, X 70", Y 65", spindle travel 27.5", longitudinal table.

- Travel 49.25", table size 48" x 60" full power 360, table load capacity 11,000 lbs

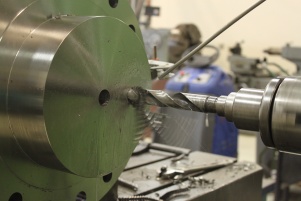

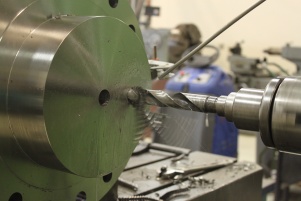

Turning - Lathes

- Mori Seiki SL303B/700 CNC, swing 26” x 36”, 25-2500 spindle rpm, 30 HP,

- Safop Sliding Gap, swing 70" x 187" between centers, gap length 69",

with tracer attachment and DRO

- Clausing, swing 21" x 32", gap length 8", centers 80" with DRO and verbal speed

- Clausing, swing 15" x 40" centers with DRO

- Clausing/Harrison 13 M300, swing 13" x 40" centers with Newall DRO

- Harrison AA, swing 13" x 25" centers with DRO

- Lodge & Shipley, swing 20.5" x 78" centers with DRO

- Kent TRL, swing 13” x 30” centers with Newall DRO

Sheet Metal

- Atlantic, hydraulic shear, 6' x .25" mild steel

- Famco shear, 4' x 12 GA mild steel

- Dries & Krump press brake 5' x 25 ton

- Two box and pan hand brakes 4'

- Box and pan hand brakes 2'

- Baileigh Electric Slip Roll SR-5016E, 50” roll x 16 gage mild steel

- Baileigh Magnetic Sheet Metal Brake, 48” x 12 gage alum

- One Manual metal roll 48" x 16 GA

- Two turret punch hand, 2" diameter x 16 gage mild steel

- Seven assorted corner notches, nibblers and table benders

Welding

- 50-amp Miller Syncrowave TIG

- 300-amp Miller MIG

- 300-amp electric Miller arc

- 200-amp portable TIG

Drilling

- Clausing single spindle, 3/4" capacity mild steel, floor type 22" x 19" table

Saws

- Marvel Model 8 vertical tilting head band saw 28" x 20"

- Two vertical band saws 16" to 39" throat x 11"

- Two Safety Speed cut panel saws 5' x10' x 1.5"

- Horizontal band saw 10" x 16"

- Cold cut saw 12" blade

Water-jet

- Omax 5555, Water-jet, X 55” x Y 55” travel, 80” x 65” table, 60,000 PSI, Kerf Computation

Electrical Discharge Machines

- Charmilles 290P Wire EDM 15.75" x 9.84" x 7.9"

- Charmilles HD 20 Hole Driller 13.8" x 9.8" x 7.9"

- Hansvedt EDM 8" x 6" x 3"

Grinders

- Thompson surface grinder 8" x 24" auto

- Two Boyer-Schultz grinders 6" x 12", manual

- Two Dunmore tool post grinders lathe attachments

- Sunnen Hone & Crane Lapmaster

- Two Panel Sanders, 37” wide

Miscellaneous Tools

- Two hydraulic presses to 50 tons

- Two arbor presses to 8 tons

- Two heat treat furnaces to 2275o F 10" x 8" x 20" is heat treat

- Two vibratory bowl finishers -- 1 cubic foot

- Zero, Bead blasting cabinets

- Bad Boy Bead blaster, SBC990, 46”(W) X 36”(D) X 35”(H)

- Chromate Conversion Line - Irridite -- tanks 55 gals.

- Paint booth 8' X 8'

- 5-ton overhead traveling bridge crane -- 20' hook lift

- Ultrasonic parts washer

Inspection Tools

- Lot micrometers 1" to 24" -- to 2" with SPC printout

- Calipers to 72" -- to 12" with SPC printout

- Wilson Rockwell hardness tester

- Two lot height gages -- to 24" with SPC printout

- Three master gage block and pin sets

- Starrett 38" x 60" tool room surface plate

- Starrett 24" x 36" tool room surface plate

PC Programming and Design

- Nine seats Surfcam V6 CAD/CAM, Solids and 2-5 Axis CNC Programing

- Gibbs CAM 2013, Solids and 2-5 Axis CNC Programing

- Eight seats AutoCad R2014 CAD

- Eight seats Autodesk Invent Professional 2014

- Ten seats SolidWorks 2013-2014 Solids Modeling Package