ATRP’s 50th Anniversary: The Research and Relationships that Made it all Possible

Fifty years and countless research projects later, leaders at the Georgia Tech Research Institute’s (GTRI) Agricultural Technology Research Program (ATRP) say its secret to success remains the same: relationships.

ATRP, which celebrates its 50th anniversary this year, got its start in 1973 with a call from the Georgia Poultry Federation requesting engineering support on issues facing the poultry industry. Since that consequential call, ATRP has developed advanced solutions in areas including robotics, advanced sensors, environmental treatment, and worker and food safety technologies that enhance the productivity and competitiveness of Georgia’s agribusiness and food processing industries. ATRP’s ultimate goal is to transition technologies from concept to commercialization as quickly and economically as possible.

“As we celebrate our 50th anniversary, I hope people see not only our enthusiasm and excitement for what we’ve accomplished, but more importantly, for our relationship with university and industry partners,” said ATRP Director Emeritus Craig Wyvill. “It’s been a special relationship.”

ATRP supports state-sponsored and contract research for industry and government agencies. For FY22, ATRP received about $2 million in funding from the state of Georgia. The organization also benefits from significant industry support, with 15 companies and associations actively participating in research projects. Over 35 individuals sit on the ATRP industry advisory committee, representing 28 different companies and organizations.

Wyvill, who served as ATRP’s longest-running program manager from 1982 to 2009, said he is proud of the way ATRP has built on his legacy while getting ahead on solving future industry challenges. “The sky was the limit then, and it still is now,” Wyvill said.

ATRP Director Emeritus Craig Wyvill (second to right) in 2013 when ATRP celebrated 40 years of service to Georgia’s poultry industry. Photo: ATRP Archive

Early Beginnings

From day one, ATRP has focused on developing new technologies that promote the economic growth of Georgia agribusiness, especially within the poultry industry, which has a $23.4 billion annual economic impact.

That mindset has served as the backbone of the organization, even as industry issues have evolved over the years.

In the 1970s, many of ATRP’s projects addressed impacts from the energy crisis on the poultry industry. At the request of the Georgia Poultry Federation, which represents the Georgia poultry industry's interests at the state and federal levels on legislative and regulatory issues, ATRP’s first project studied noise generation and control in poultry processing plants.

From that project, ATRP developed one of the first sound-absorbing panels to be approved by the U.S. Department of Agriculture (USDA). These washdown-protected, noise-absorbing panels were ultimately manufactured commercially.

“In the early 1970s, utilizing a one-call service at the University System of Georgia Board of Regents, I asked for assistance in noise control problems and was referred to Georgia Tech,” recalled Abit Massey, president emeritus of the Georgia Poultry Federation. “It was the beginning of a long and productive relationship.”

Other top priorities for ATRP in the 1970s were waste management and workplace safety as new regulations were implemented with the advent of the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA).

Left: At the request of the Georgia Poultry Federation, ATRP developed one of the first USDA-approved sound-absorbing panels to reduce noise levels in processing plants. Right: ATRP’s state-of-the-art computerized broiler house management system for monitoring and controlling growout operations. Photos: ATRP Archive.

During the 1980s and 1990s, ATRP explored ways to incorporate emerging technologies, such as computer systems and robotics, into solutions for the industry. Other trends that shaped ATRP’s research during these years included environmental sustainability and compliance, plant maintenance, ergonomics and worker safety, and food safety.

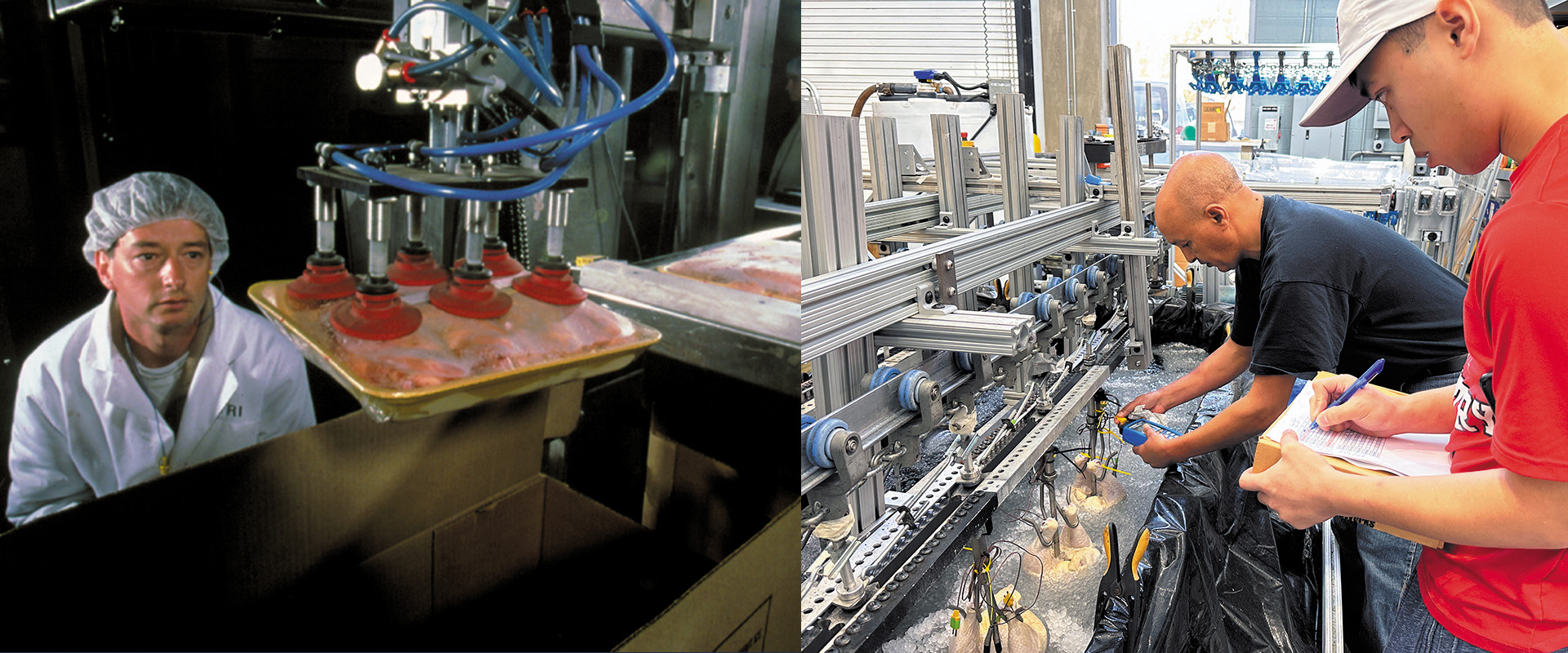

For one project, ATRP developed a broiler house computer system, or a “farm computer,” that was designed to allow a farmer to keep continuous, accurate records of the conditions inside a broiler house, including its temperature and humidity levels, feed and water consumptions, and ammonia levels. The organization also developed one of the first low-cost robotic systems that loaded tray packs of poultry products into shipping cartons.

One of the first computer systems designed for real-time data collection from the processing plant floor. Photo: ATRP Archive

In the 2000s, ATRP’s research focused on the development of machine vision and automation systems for the screening of whole birds and portions for quality inspection and sorting. In the 2010s, the organization worked closely in the areas of advanced sensing and environmental technology. One of the projects introduced around this time included a novel filtration system for water recycling and byproduct recovery in poultry processing operations.

The project has since been commercially licensed to Watson Agriculture and Food, a subsidiary of venture capital firm Watson Industries that invests in technologies to solve major world problems.

“I cannot say enough about the pedigree of Georgia Tech and how the school offers a platform for advanced thinking and the opportunity to develop novel solutions for complex challenges,” said Trey Watson, founder and CEO of Watson Industries.

Although much attention is given to the rivalry between Tech and the University of Georgia (UGA), Mike Lacy, who is the former head of UGA’s Poultry Science Department and who has worked with ATRP since 1985, including serving on its advisory committee, called the relationship between the two universities a symbiotic one.

“GTRI brings an incredible ability to look at problems from an engineering and technical perspective, while UGA has unmatched expertise on the live production, processing, and food safety side of the poultry industry,” Lacy said. “We always came up with better solutions, ideas, and service to the industry together than apart.”

Left: Wayne Daley (left) works on ATRP’s automated system that records and analyzes the vocalizations of birds to evaluate their well-being during the growout cycle. Daley has been with ATRP since 1982 and most recent served as the associate division chief of GTRI’s Food Processing Technology Division (now the Intelligent Sustainable Technologies Division). He has played a key role in establishing ATRP’s computer system and automation research. Right: ATRP’s novel filtration system for water recycling and byproduct recovery in poultry processing operations. The project has been commercially licensed to Watson Agriculture and Food, a subsidiary of venture capital firm Watson Industries that invests in technologies to solve major world problems. Photos: ATRP Archive

Laying the Foundation

The technologies ATRP used and developed in its early days may have been less advanced than those of today, but they gave the organization a glimpse into technology’s transformative potential, said Wayne Daley. Daley has been with ATRP since 1982 and most recently served as the associate division chief of GTRI’s Food Processing Technology Division (now the Intelligent Sustainable Technologies Division). “Back then, the computer systems we were using had a lot of room for development, but they gave us a good understanding of what was possible,” Daley said.

Daley was instrumental in establishing ATRP’s computer system and automation research, including developing computer vision and intelligent systems to inspect poultry products for contaminates and expedite many common poultry processing operations.

Looking back on his career at ATRP, Daley said he most enjoyed doing work that didn’t feel like “work” and developing lifelong friendships.

“Our technical achievements have all been rewarding, but what’s even more amazing is that I’m still friends with a lot of people I worked with over the years,” Daley said. “Craig (Wyvill), who hired me, and other program managers, were always open to letting us try new things. I feel fortunate to have had a job I enjoyed doing.”

Daley added that students play a huge role in ATRP’s success by bringing in fresh perspectives to projects.

ATRP works year-round with students from the high school to postdoctoral levels, including hosting high schoolers for GTRI’s high school summer internship program and students at Georgia Tech who are participating in its professional student programs – which includes the Cooperative Education (co-op) program, internships and undergraduate student assistantships, and graduate research assistantships.

ATRP also hosts students each year in its Abit Massey Student Internship Program. The program, which was established in 2019, gives Georgia Tech undergraduate students an opportunity to work with ATRP researchers on real-world challenges facing food production and processing.

Louise Zhuang was the first participant in the Abit Massey Student Internship program, who is now earning her Ph.D. at Stanford University in electrical engineering. Zhuang received her bachelor’s degree, also in electrical engineering, from Georgia Tech in 2020.

During her time at ATRP, Zhuang worked on a project that looked to incorporate virtual reality (VR) into common poultry processing operations, such as deboning. Poultry deboning, which involves cutting the breast meat and wings from a poultry carcass, is a task that is largely completed by skilled workers. However, the repetitive nature of this job is not just monotonous, but it can also lead to injury and diminished yield and profitability.

ATRP has filed a provisional patent for its VR research and is also working with the Georgia Research Alliance (GRA) to develop a commercialization roadmap for the technology.

“Since this process is tedious, we wanted to automate this task with robotics,” Zhuang said. “Basically, we developed a method to calculate deboning knife trajectories for individual chickens, and we were able to do some initial testing in the VR space and with a real-life robotic arm.”

Zhuang said her experience at ATRP exposed her to VR’s potential and gave her coding experience in several programming languages, from C and C++ to Python and MATLAB, which she still uses at Stanford. She said young minds add value to ATRP by bringing unique experiences to the research.

“As a student, it was nice to be taking classes while also working on projects with real-world applications,” Zhuang said. “Once students have those skills, it’s a lot easier to start working as a full-time employee or graduate student.”

Left: Gary McMurray, a GTRI principal research engineer, division chief of GTRI’s Intelligent Sustainable Technologies Division, and the associate director for Georgia Tech’s Institute for Robotics and Intelligent Machines, is pictured next to one of the first low-cost robotic systems that ATRP developed to load tray packs of poultry products into shipping cartons. Right: GTRI Principal Research Engineer Aklilu Giorges (left) works on ATRP’s innovative in-line immersive chilling system that uses ice slurry as an alternative chiller medium. Photos: ATRP Archive

Next 50 Years and Beyond

ATRP’s research over the past 50 years has been most clearly associated with enhancing agricultural processes, but it is also having an impact in the defense sector, noted Gary McMurray, a GTRI principal research engineer and division chief of GTRI’s Intelligent Sustainable Technologies Division. He is also the associate director for the Institute for Robotics and Intelligent Machines (IRIM) at the Georgia Institute of Technology (Georgia Tech).

For example, ATRP has applied its robotics research to improving inventory management processes at the Marine Corps Logistics Base in Albany, Georgia. ATRP is also looking to utilize its chemical and biological sensing research to help warfighters detect harmful chemical agents on the battlefield.

“I am a firm believer that when you bring together scientists and engineers, you’re going to constantly be finding new opportunities, and to me, that’s just exciting,” McMurray said.

Jeff Buhr, an animal physiologist scientist at the USDA’s Poultry Microbiological Safety and Processing Research Unit and an adjunct professor in UGA’s Poultry Science Department, has worked with ATRP since the 1990s.

Buhr has guided ATRP on several projects, including automated poultry deboning and using ice water slurry to reduce chilling times for poultry carcasses. For poultry deboning, Buhr used his background in anatomy to identify reference points and the optimal cutting spots for the robot-guided knife.

“It’s been a good relationship,” Buhr said. “I’ve worked with them to answer questions such as, ‘How is this research going to be applied?’ to ‘How can we streamline these processes further?’”

He added that ATRP’s focus on developing commercially viable solutions has a hand in promoting economic growth in Georgia.

“There are probably 300 to 750 people that work in a poultry processing plant, and for many of them, it’s their only local job opportunity.”

ATRP’s current program manager, Doug Britton, said he is proud of the way ATRP’s research and relationship with external stakeholders has grown over the past 50 years.

“Our 50th anniversary serves as an important reminder of the impact our program has had over the years, which would not have been possible without the immense support we have received from our industry, academic, and government partners,” Britton said. “It’s been amazing to witness how our team’s focus on technology transfer has led to the development of innovative solutions that enhance economic impact in Georgia and beyond.”

Wyvill agreed.

“I don't know of many other programs, or industry links like this, that exist and have existed for this long,” he said. “We are excited about the impact we have made, but we’re not resting on our laurels. We’re still pushing those envelopes.”

RELATED LINKS

This episode of the Georgia Tech Research Podcast begins a special series commemorating the 50th anniversary of the Georgia Tech Research Institute’s Agricultural Technology Research Program (ATRP). Host Stephanie Richter, a GTRI Research Scientist, talks with ATRP Director, Doug Britton.

Gary McMurray, GTRI Principal Research Engineer and Division Chief, (GTRI ISTD) describes the Technology for Society pillar of the GTRI Project Portfolio.

Writer: Anna Akins (anna.akins@gtri.gatech.edu)

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia USA

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees supporting eight laboratories in over 20 locations around the country and performing more than $800 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.

GTRI IS HIRING. LEARN MORE HERE.